Top Dog Entry: Mark Emly, TyMar Tool Works

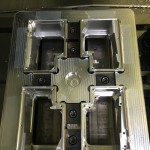

We inherited a couple of jobs and the fixtures. The old fixtures took up a lot of space on the table and wasted a lot of product. We changed the chamber fixture over to two pallets using mitee-bite uni-force clamps and with each run we now get 20 completed parts as opposed to 12. With a more compact set up my wife can easily set the pallets up to run on her own without any help from me. Our run time has gone from 4 ten hour days to 2 nine hour days finally making the job profitable.

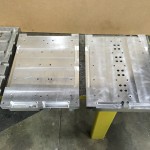

For the box set up I made a compact aluminum pallet that the parts fit down into using mitee-bite uni-force clamps replacing a much larger pallet that used pneumatic cylinders. The old fixture put out 2 completed part each run and because of the size of the fixture and the unreliable clamping of the part, we were only able to get 7 to 8 parts per hour. The new pallet system puts out 2 completed parts and we can achieve 14 parts per hour. Also, with the compact system it fits into the vise and we have modified the vise so that the set up time is only a few minutes, versus an hour with the old fixture, and the vise set up allows an operator to change the set up instead of having a set up person do it.

I have also included a few pictures of set ups using the Mitee-Bite Talon grip jaws, one of the parts is showing an action shot of the milling the 420 prehardened stainless steel with a ½” cutter, 1.300” doc and .025” step over at 1050 IPM, these Talon grip jaws have been had the most ROI of any thing that I have ever purchased.

Thanks Mitee Bite for having products that help us reduce setup time and increase profits.