Top Dog Entry: Mitch Niemela, Toolcraft Inc.

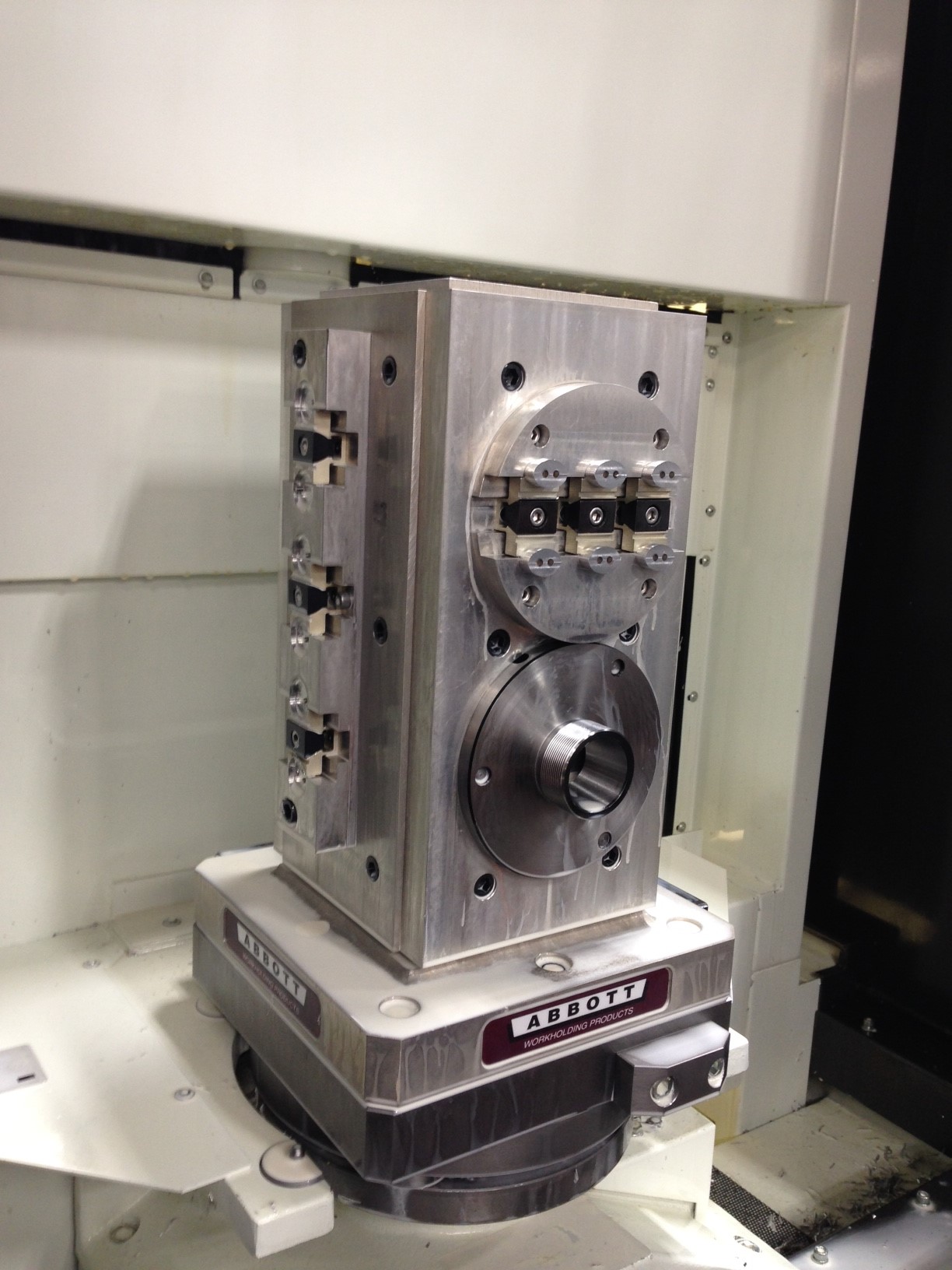

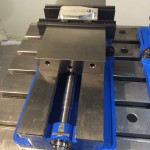

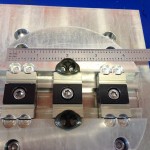

When looking at workholding for these parts, we knew we needed something more compact than a typical vise. We looked into everything from completely custom manufacturing a solution in-house, to having a completely custom solution manufactured for us. We did not have the resources to start completely from scratch, but we did want to have a hand in designing the fixtures so that we could easily adapt as the project progressed. The Mitee-Bite clamps fit what we were searching for exactly. We downloaded the Machinable Uniforce clamp solid models that we selected, dropped them into plates we designed in-house, and were able to quickly and easily come up with a complete set of fixtures for this family of parts. Machining the fixtures was simple; the instructions for setting the fixtures properly were easy to follow and worked right the first time. Clamping performance is great as well, which is important with the aggressive toolpaths we applied to the parts.

Since the first fixture for this family of parts was successfully implemented, we made fixtures that used Pitbull, regular Uniforce and ID Expansion clamps. Every time we implemented a Mitee-Bite component, the process was simple and pain-free. The components are affordable and in-stock. They are very well supported if anything comes up. There are many reasons why we have chosen to use Mitee-Bite components and will continue to do so.

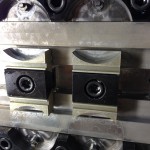

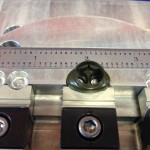

We came across an interesting challenge with a shorter-run production Fitting for the Aerospace industry. This part is 7075-T651 and the geometry is pretty simple. The order was for about 100 parts. The challenging feature is a Ø.6875-.6880 bore thru one end. When using a typical flat jaw/parallel or step jaws setup, the part needs to be squeezed very tight in order for the part not to come out of the vise. When flat jaws are used, the bore tolerance cannot be held near in tolerance, because the part is bored under stress, then releases after unclamping resulting in an out-of-round condition.

With the TalonGrip jaws, we clamp on tablesawn material blanks (no need to square-up), clamp to approx. 200in./lbs, unclamp, then re-clamp to 70in./lbs. The overclamp/re-clamp method makes little indentations in the material that allow the part to be final clamped under much lower stress but still retain enough holding power not to come loose during rouging. This part would get a custom fixture if it were to go into higher production, but TalonGrip jaws allowed Toolcraft to easily machine these critical parts in-spec without making a custom fixture for this lower production run.