NEW! Patent Pending WATERJET/PINCHER CLAMP

June 2nd, 2025

WATERJET_PINCHER CLAMP INFO

is the innovator of compact,

low-profile edge clamps geared towards improving productions and providing solutions for

difficult workholding applications.

(US & CANADA ONLY) | 603-539-4538 [email protected]

https://roushyatesengines.reallyinteractive.media/

High-density workholding offers many benefits, a prime one being the ability to run a machine tool longer unattended. Click here to read more!

Our supplier for the plastic red handles used on the original collet wrench, unfortunately went out of business – fortunately this provided an opportunity to produce a better product! Now with an aluminum, knurled handle for improved grip and includes a cross-hole when additional torque is required, by simply inserting screwdriver to tighten or loosen […]

Mitee-Bite Products has introduced Mitee-Grip GEN II, the next generation in low temperature wax workholding.”Prior to these new compounds, some materials were next to impossible to secure and withstand machining forces, especially phenolic, glass, honeycomb and most plastics,” said a company spokesperson.”We used the Blue Mitee-Grip GEN II for parts 1/2 in. x 1/2 in. […]

Mitee-Bite Products introduces the NEW Heavy-Duty TalonGrip™ grippers! Designed for those aggressive operations on harder materials while providing the ability to hold about any shape you can imagine – that’s the Mitee-Bite Grip! Standard gripping height or elevated for cutter clearance by resting part on the Original VersaGrip™ gripper or custom made pucks in the […]

Mitee-Bite Products in Center Ossipee, NH would like to congratulate Russ Hegarty as the winner of a Talongrip™/Versagrip ViseJaw 6” Combo Kit given away at the SHOT Show in Las Vegas NV, January 20-21. Russ is the owner of JT Arms in Prescott, AZ. They buy, sell and trade new and used firearms, provide full-service […]

Roush Yates Partnership Extension with Mitee-Bite Products

Mitee-Bite Products introduces the Power Bar™ – a modular platform designed to elevate your capabilities with some of the strongest clamps in today’s market. Utilizing any of the DK model OK-Vise® Wedge Clamps or our largest Pitbull® Clamps, you have the options to elevate your workpiece for mill/drill through operations or forcing your parts onto […]

Mitee-Bite Products introduces the Heavy Duty™ T-Slot Clamps – capable of generating over 20,000 pounds of pressure. This design utilizes some of the strongest lowest-profile clamps in the industry. The Pitbull® and OK-Vise® Clamps can be used on the same base with so many configurations you’re sure to have more holding force than needed!

The “Titan – American Built” series, first aired in 2014, featured episodes dedicated to showing CNC shops the best way to maximize their production with modern machining practices and is still airing on MAVTV today. Titan Ty Gilroy recently created a new and innovative platform, which is now accessible through the TITANS of CNC Academy […]

FIFTY YEARS IN THE MAKING FORD WINS POLE AND LM GTE PRO CLASS AT LE MANS! LE MANS, France, JUNE 19, 2016 –History has been made! The No. 68 (Joey Hand (US), Dirk Müller (GER), and Sébastien Bourdais (FRA)) wins the 84th running of the 24 Hours of Le Mans. Fifty years after Ford’s legendary […]

We are counting down to the start of the 2016 FIA World Endurance Championship season in Silverstone, Great Britain. Where the Ford GTs will make their official overseas race debut on April 17th. During this same weekend the IMSA series will take over the streets of Long Beach, CA to run the third WeatherTech Sportscar […]

The Daytona 500 is here! The Great American Race! Roush Yates Engines is very excited about kicking off the 2016 NASCAR race season. Roush Yates Engines is the exclusive engine manufacturer of the Ford FR9 V8 engine; that will power the Ford Performance NASCAR vehicles. We will support a combined 17 NASCAR Sprint Cup, Xfinity […]

This fixture for a contour part nested inside a contoured pocket and clamped with Pitbull clamps around outside of part to finish the thickness that followed the contour. For a size reference, I started with a 11″ X 11″ x 9″ block to make his fixture. The setup is mounted on a trunion in a […]

We at Cassavant machining employ numerous Mitee-Bite technologies on a fixtures on nearly 50% of our machining setups for 3, 4 and 5 axis mill machining centers. Too many to count! I chose a job from our horizontal machining cell to submit. We were able to complete 95% of the of the part features. Op […]

Strongest modular OK-Vise fixture on the planet!!

I needed a simple fixture that would locate on a ramped surface to hold parts in place for surface grinding. I talked with Tim Krafton in the engineering department at mitee-Bite a few times during this design and he gave me pointers since I had never used the uniforce clamps before. When finished, I was […]

The initial purchase order for this job was 200 pieces per year which consisted of milling the 4-operation piece one at a time. When the customer increased their order to 2000 per year, we needed a more efficient way to do this job. Being a small job shop, we could not afford to have a […]

5 axis tombstone milling. 16 products in 1 run, complete finished. Mitee-Bite had the perfect solution to hold my parts. I used MiteeBite-56050and MiteeBite-33075 to hold my parts.

Since all AFCO products start out as aluminum extrusion we are faced with small parts, with thin wall but need to produce high volumes. For the 13 years I have been with AFCO we have used several types of Mitee-Bite clamps to build fixtures and they always perform great. The 61500 clamps hold the parts […]

When looking at workholding for these parts, we knew we needed something more compact than a typical vise. We looked into everything from completely custom manufacturing a solution in-house, to having a completely custom solution manufactured for us. We did not have the resources to start completely from scratch, but we did want to have […]

These are the pictures of the fixture , we use it to machine bars and blocks , we hold different sizes , from 11 feet bars to 2” blocks we do machining around the parts, chamfers and threaded holes , we drill and tap 800 holes per set up , quantity of parts from 6 […]

1, fixture holds 24 parts 12 in the vertical and 12 horizontally 2, The parts on the front (vertical ) are recessed .010 in. This face is also the datum of the fixture and clamped against the fixed jaw of the vise. 3, The parts on top of the fixture stick up .125 in. This […]

I have a whole bench full of your products. Before I started using Mitee Bite products, We were only fixturing in softjaws. After I started to implement Mitee Bite, I have seen a time reduction of over 300% in a couple of the parts we manufacture. In one instance we used to run one vice, […]

Here is our latest fixture using your Pitbull clamps. The parts on the left side of the fixture get cut in half then transferred to the right side of the fixture to get a flat cut on top. These are brass cable clamps used in our digital thermometer probes. These parts are held at +.005 […]

I use your products frequently and I have never had any problems and they are so useful and easy to set up. I will start telling you that initially the component I am talking about used to be done one side at a time using 3 different vices as shown in ‘original’ picture. The holes […]

I wanted to share what our First Robotics team, FRC Team #971 Spartan Robotics of Mountain View High School is doing with Mitee-Bite fixture clamps. In 2014 several mentors and a few students set out to design and build a CNC router to help fabricate parts for the competition robots. The CNC router was completed […]

The raw stock size is 16″ diameter x 4.15″ tall. The part weighs 83.4 lbs and we are holding it down with two ¼-20 Pitbull clamps pushing against a TalonGrip on the far side. The parts machined perfectly without a single part moving on the fixture. Even though we only had a total of 5 […]

The initial purchase order for this job was 200 pieces per year which consisted of milling the 4-operation piece one at a time. When the customer increased their order to 2000 per year, we needed a more efficient way to do this job. Being a small job shop, we could not afford to have a […]

We inherited a couple of jobs and the fixtures. The old fixtures took up a lot of space on the table and wasted a lot of product. We changed the chamber fixture over to two pallets using mitee-bite uni-force clamps and with each run we now get 20 completed parts as opposed to 12. With […]

Some workpieces, like those that are oddly shaped, large or delicate, can be a real pain in the neck. Delicate geometries, thin walls and shapes more flexible than a ballerina what’s the best way to securely grab hold of them? Gerard Vacio, workholding systems specialist at BIG Kaiser Precision Tooling Inc., Hoffman Estates, Ill., said […]

Straightline Precision Industries Inc. recently faced the challenge of machining an aerospace component in the most efficient and accurate way possible. The component, part of the nose gear steering system of a commercial aircraft, required numerous operations and tight tolerances. “The traditional method of making this part in six operations on a 3-axis vertical mill […]

Maximize spindle uptime, minimize operator intervention. Such are the aspirations of countless manufacturing operations throughout the country, and Eric (Sol) Sun’s new company in Orange County, California is no exception. And, like many others, this fledgling shop owes much of its success in meeting those goals to one particular equipment configuration: horizontal machining centers (HMCs) […]

Shuttle Aerospace recently implemented 4th axis machining across all its pre-existing 3-axis vertical mills by creatively utilizing new workholding devices. This produced several challenges. The tooling required had to bemore compact and efficient to allow for the lessened work envelope created by the 4th axis and tailstock. It also had to rotate at high speed […]

Cross-country and downhill cyclists appreciate having durable, lightweight parts while manufacturers of those parts, such as Straitline Components, like to reduce waste and boost productivity. To reduce manufacturing costs, the Sidney, British Columbia, company tries to minimize the amount of material required for effective workholding, but found throughput suffered because of its previous workholding method. […]

Many shops look to that old standby, a 6″, 2-jaw vise, for their machining centers’ workholding needs. True, vises are economical, simple to use and can grip most anything. They’re also a big waste of space. High-density workholding, on the other hand, makes the most of a machining center’s available real estate. By getting more […]

Mitee Bite Products Inc. and TE-CO officially announce their partnership in serving the industrial metalworking industry. Both companies have built substantial reputations for quality workholding products & world class customer service. Mitee Bite Products Inc. (Ossipee, NH) is a leading manufacturer of workholding systems and components for small to medium workpieces. Mitee Bite Products Inc. […]

Smith & Wesson located in Springfield, MA is well known the world over, for it’s high quality gun manufacturing. It’s facility is over 500,000 square feet and they employee in excess of 600 people. Perhaps less known is the Specialty Services division of Smith & Wesson, which does various types of contract machining. Recently the […]

Quality Design & Mfg. of Oxford, CT has been in the machining business for over 20 years. The owners, Marty and Sue Martovich have recently developed a joint venture with Richard Grano. With the new management and change of direction, QDM moved to a larger more modern high tech facility to accommodate additional machinery acquired […]

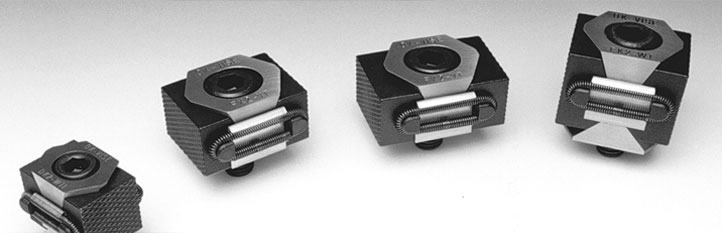

The OK-VISE® clamp is a wedge activated clamp. As the screw is tightened, the clamp expands and pulls the workpiece down at the same time. Small in size and high in clamping force, this low profile clamp is available in many different sizes. The OK-VISE® clamp is precision ground on all moving surfaces to ensure […]

Mitee-Bite Products specializes in low profile edge clamps in several different styles and sizes for jigs and fixtures, including a range for micro machining. The miniature clamps are available in cam action design, wedge design and Pitbull® design which bites in and pulls down. Some of these clamps are less than 1/8 inch high and […]