Top Dog Entry: Jez Pring, TWM Technology

I use your products frequently and I have never had any problems and they are so useful and easy to set up.

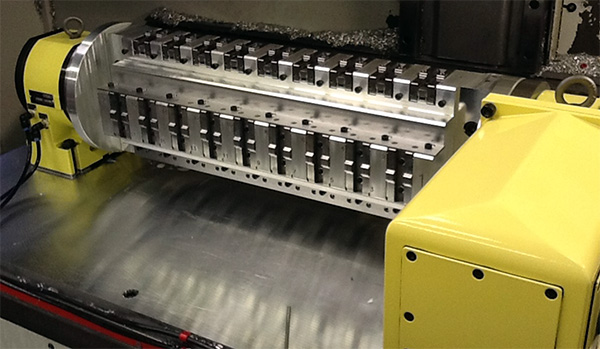

I will start telling you that initially the component I am talking about used to be done one side at a time using 3 different vices as shown in ‘original’ picture. The holes are fairly complex consisting of thread milled portion and a series of tied up counterbores to suit solder joints and fixings.Now this would take approximately 16 minutes per part with loading time which meant about 30 parts per day.So I designed and made a trunion fixture using your clamps and invested in a 4th axis and now the parts take approx 2.5 minutes each and 72 of these are loaded at a time. This meant there was enough time to get a 3rd batch running before the end of the day to run when lights out so we are now machining 216 parts a day. We made 4600 parts this year so you can see how massive a saving was made by doing it this way.

I hope this was of some interest as it is something i am quite proud of.

- Original