Dyna-Force® Clamps

Measurements Available: Metric

Dyna-Force® Clamps

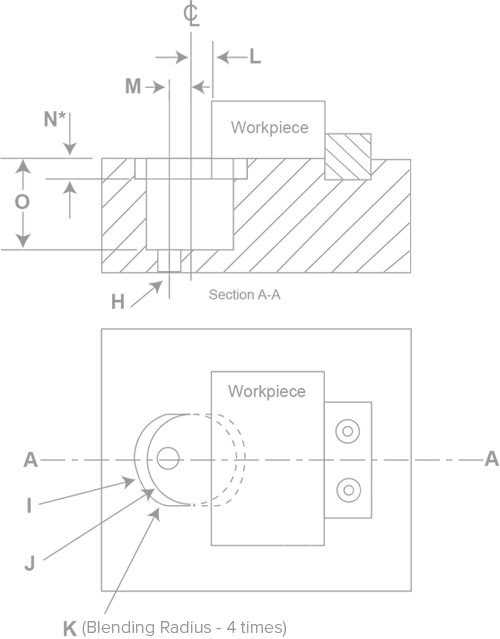

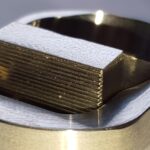

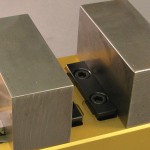

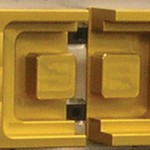

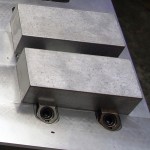

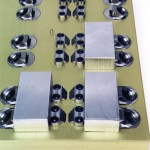

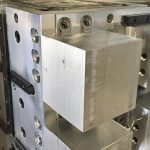

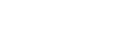

The majority of the Dyna-Force® clamp is below the surface of the fixture which provides excellent clamp support and makes for a very low profile. The clamp jaw slides on an angle for positive downforce.

The clamp jaw is available with smooth or serrated faces.

The support surface of the Dyna-Force® clamp can be installed flush with the fixure plate or raised to hold the workpiece off the fixture, enabling drill-through.

PATENT NO. 5964458 |

|

Metric

| Part No. |

Clamp Jaw† & Hardness |

A* | B | C | D | E | F | — Min |

G Opt. |

— Max |

Clamp Travel |

Drive Screw |

Key Size |

Max Torque |

Holding Force |

Repl. Clamp Jaw Insert** |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 28314 | CAD | Smooth 34RC | 20.00 | 24.90 | 19.00 | 19.90 | 4.50 | 13.50 | 3.25 | 5.00 | 6.75 | 2.0 | M6x12mm | 5mm | 7.3 (Ft/Lbs) 9.9 (N.m) |

2,000 (Lbs) 8896 (N.) |

28480 (smooth) |

| 28318 | CAD | Serrated 44RC | 20.00 | 24.90 | 19.00 | 19.90 | 4.50 | 13.50 | 3.25 | 5.00 | 6.75 | 2.0 | M6x12mm | 5mm | 7.3 (Ft/Lbs) 9.9 (N.m) |

2,000 (Lbs) 8896 (N.) |

28482 (serrated) |

| 28320 | CAD | Smooth 34RC | 25.00 | 29.90 | 24.00 | 24.90 | 5.00 | 15.00 | 4.50 | 6.50 | 8.25 | 2.2 | M8x16mm | 6mm | 17.6 (Ft/Lbs) 23.9 (N.m) |

2,600 (Lbs) 11565 (N.) |

28484 (smooth) |

| 28322 | CAD | Serrated 44RC | 25.00 | 29.90 | 24.00 | 24.90 | 5.00 | 15.00 | 4.50 | 6.50 | 8.25 | 2.2 | M8x16mm | 6mm | 17.6 (Ft/Lbs) 23.9 (N.m) |

2,600 (Lbs) 11565 (N.) |

28486 (serrated) |

| 28324 | CAD | Smooth 34RC | 30.00 | 37.90 | 29.00 | 29.90 | 7.00 | 20.00 | 4.50 | 7.50 | 10.75 | 3.8 | M10x18mm | 8mm | 35.3 (Ft/Lbs) 41.9 (N.m) |

3,200 (Lbs) 14234 (N.) |

28488 (smooth) |

| 28328 | CAD | Serrated 44RC | 30.00 | 37.90 | 29.00 | 29.90 | 7.00 | 20.00 | 4.50 | 7.50 | 10.75 | 3.8 | M10x18mm | 8mm | 35.3 (Ft/Lbs) 41.9 (N.m) |

3,200 (Lbs) 14234 (N.) |

28490 (serrated) |

†Smooth jaw only will have relief cut

*Body diameter

**Clamp Jaw Drive Screw and Retaining Ring Included.

|

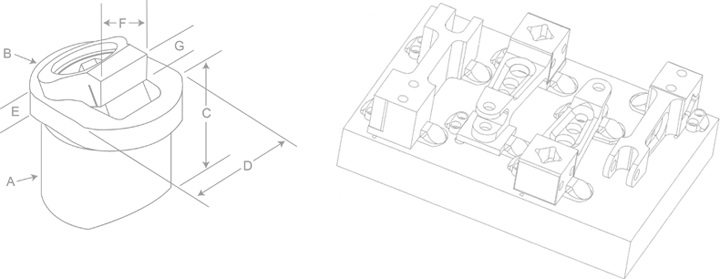

Example: 20mm clamp when CL of bore is 4.90mm from edge of workpiece |

| Part No. | H* | I | J | K | L | M | N | O |

|---|---|---|---|---|---|---|---|---|

| 28314/28318 | M5 x 10mm or 10-24 x .375” SHCS | 25.00 | 20.00 | 6.00 | 4.90 | 5.00 | 4.50 | 20.00 |

| 28320/28322 | M6 x 14mm or ¼-20 x .500” SHCS | 30.00 | 25.00 | 6.50 | 5.65 | 6.00 | 5.00 | 25.00 |

| 28324/28328 | M8 x 16mm or 5/16-18 x .625” SHCS | 38.00 | 30.00 | 8.00 | 7.05 | 7.50 | 7.00 | 30.00 |

*Recommended minimum “under head” screw length.