Uniforce® Clamps

Measurements Available: Inch, Metric

Uniforce® Clamps

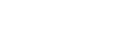

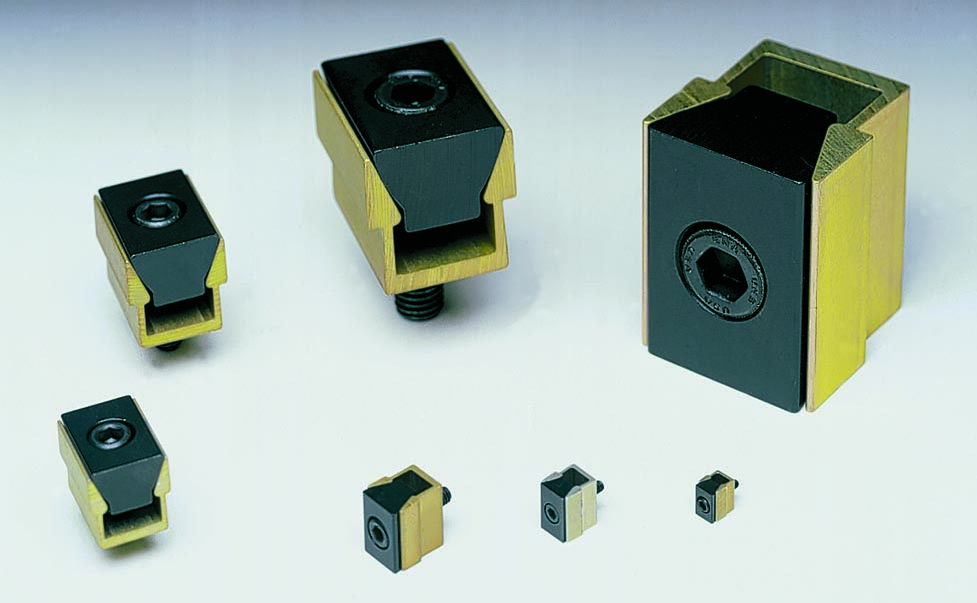

The compact, economical MITEE-BITE Uniforce® Clamp enables you to fixture more parts on the machine table. The specially designed steel wedge spreads the clamping force uniformly on both sides of the 7075-T6 aluminum channel and is one of the best solutions for high density applications.

– Increases production.

– Minimizes tool changes.

– Holds two parts with equilateral clamping action.

– Ideal for clamping flat or round work pieces.

– Reduces wasted space.

– Easily mated to hydraulic pull cylinders.

– Ideal for pallet changers.

– Shown with our Locating Rails

– Available in Long Lengths

|

Inch

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

†F is the distance needed between workpieces for clamp clearance. Drill and tap mounting hole on the center of F dimension.

*Clamps available in bulk (50+ pieces, contact Mitee-Bite Products for more information).

Metric

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

F† The distance needed between workpieces for clamp clearance. Drill and tap mounting hole on the center of F dimension.

*Clamps available in bulk (50+ pieces, contact Mitee-Bite Products for more information).

Applications

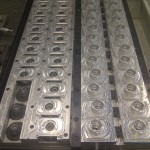

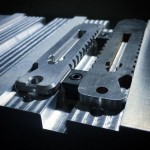

- Image courtesy of Jesse Taber

- Image courtesy of @freakingreen

- Image courtesy of @grayopscnc

- Image courtesy of @themodernmachinist

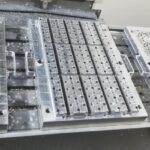

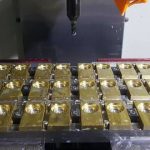

- Peter Stokes – Mitee-Bite Facebook Community – My latest mitee bite fixture. All three have removable top plates located with 4 Mitee Bite ID clamps while operator reloads another set of identical top plates while machine continues to run. 60 complete parts in 2.5 hrs(can speed up the program a bit) with 4 total operations on each part. Fun to design and make.

- Peter Stokes – Mitee-Bite Facebook Community – My latest mitee bite fixture. All three have removable top plates located with 4 Mitee Bite ID clamps while operator reloads another set of identical top plates while machine continues to run. 60 complete parts in 2.5 hrs(can speed up the program a bit) with 4 total operations on each part. Fun to design and make.

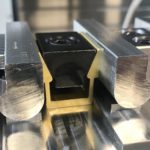

- @jack_vanderpols – Needed a removable work stop for quickly setting up these parts that are machined on 3 faces. Needed a solution that can be removed but also wouldn’t be forgotten by the operator. Toyed with ideas of varying difficulties for a day and finally decided on easy does it. Block of aluminum, magnets, m6 cap screws, and some tennis string. Turned out effective for a minimal amount of effort put in.

- Image courtesy of @jack_vanderpols.

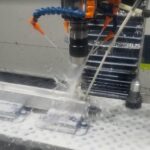

- Image courtesy of @freakingreen. “Setting up pallets again to rack and stack more aluminum and get numerous parts done in one set up.”

- Image courtesy of @tecuscncteknolojileri

- Image courtesy of @tecuscncteknolojileri

- Image courtesy of @advancedmachineengineering

- Image courtesy of @absolute_cnc_sa

- Image courtesy of @djprecisionmachine

- Image courtesy of @officinescalella

- Image courtesy of @gmc_cnc_machining

- Image courtesy of @innovatools_inc