Three Days of Innovation, Precision Engineering, and Manufacturing Solutions!

Step into a world of possibilities for your business as the size of this event has doubled to unveil an impressive 100,000 square foot display area. This year’s Oktoberfest will be twice the size of the 2023 show – bigger and better than ever!

Come and Experience:

40+ Live Machine Demos

90+ Premium Suppliers

Expert Led Daily Seminars

Indulge in Traditional Oktoberfest Food

This is your opportunity to connect with our expert Applications Engineering and Service Teams, explore our complete manufacturing and industrial solutions, and discover how we can help you succeed. Whether you’re a current or prospective customer, small or large company – all are welcome and there’s no cost to attend.

Click here for more information! Location: 15150 25th Avenue North, Plymouth, MN 55447

Smith & Wesson located in Springfield, MA is well known the world over, for it’s high quality gun manufacturing. It’s facility is over 500,000 square feet and they employee in excess of 600 people. Perhaps less known is the Specialty Services division of Smith & Wesson, which does various types of contract machining.

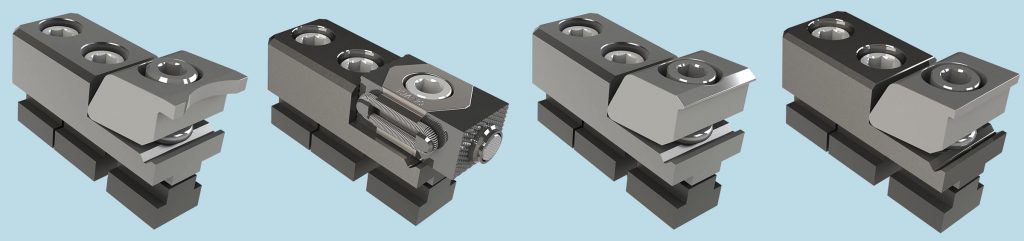

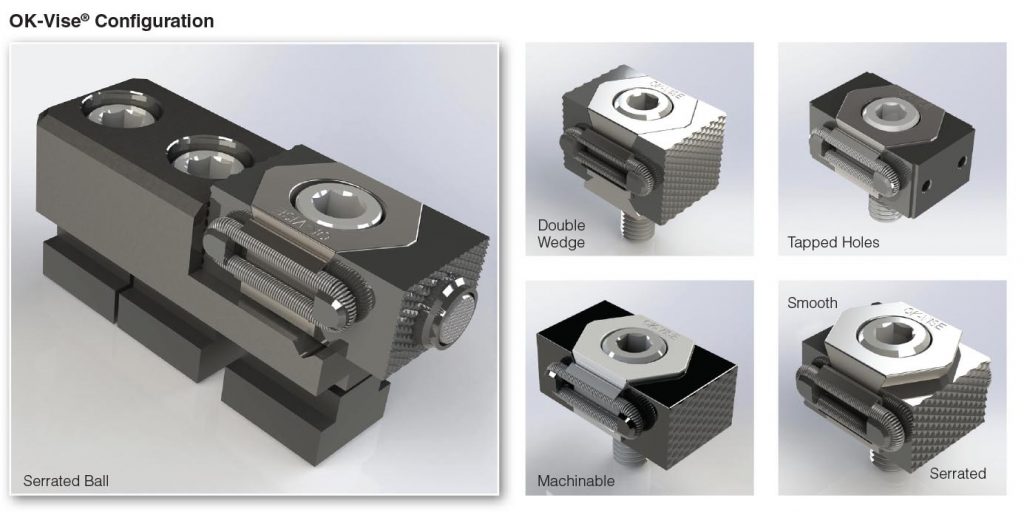

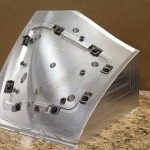

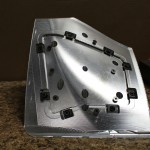

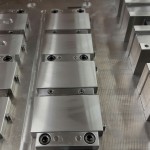

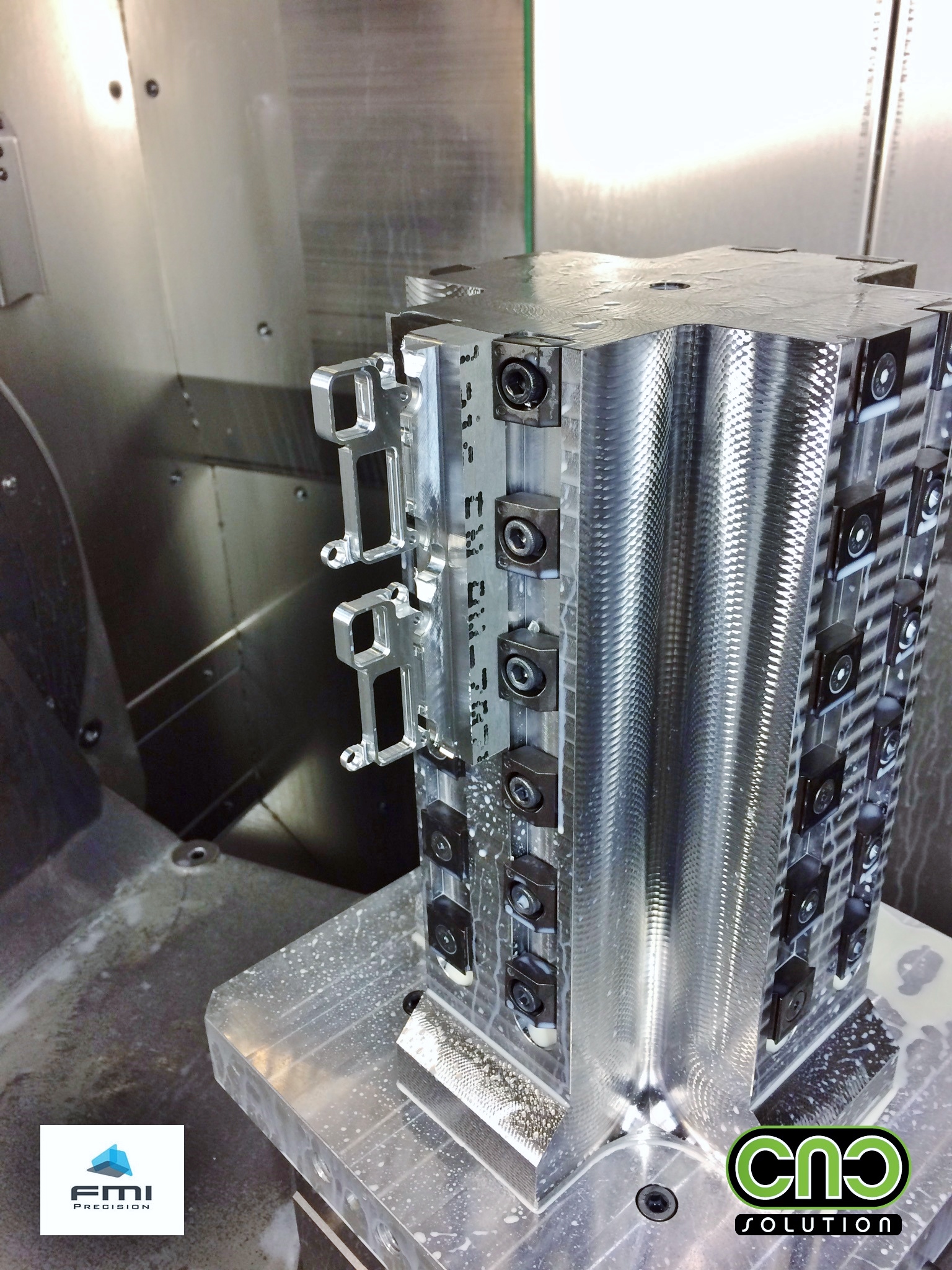

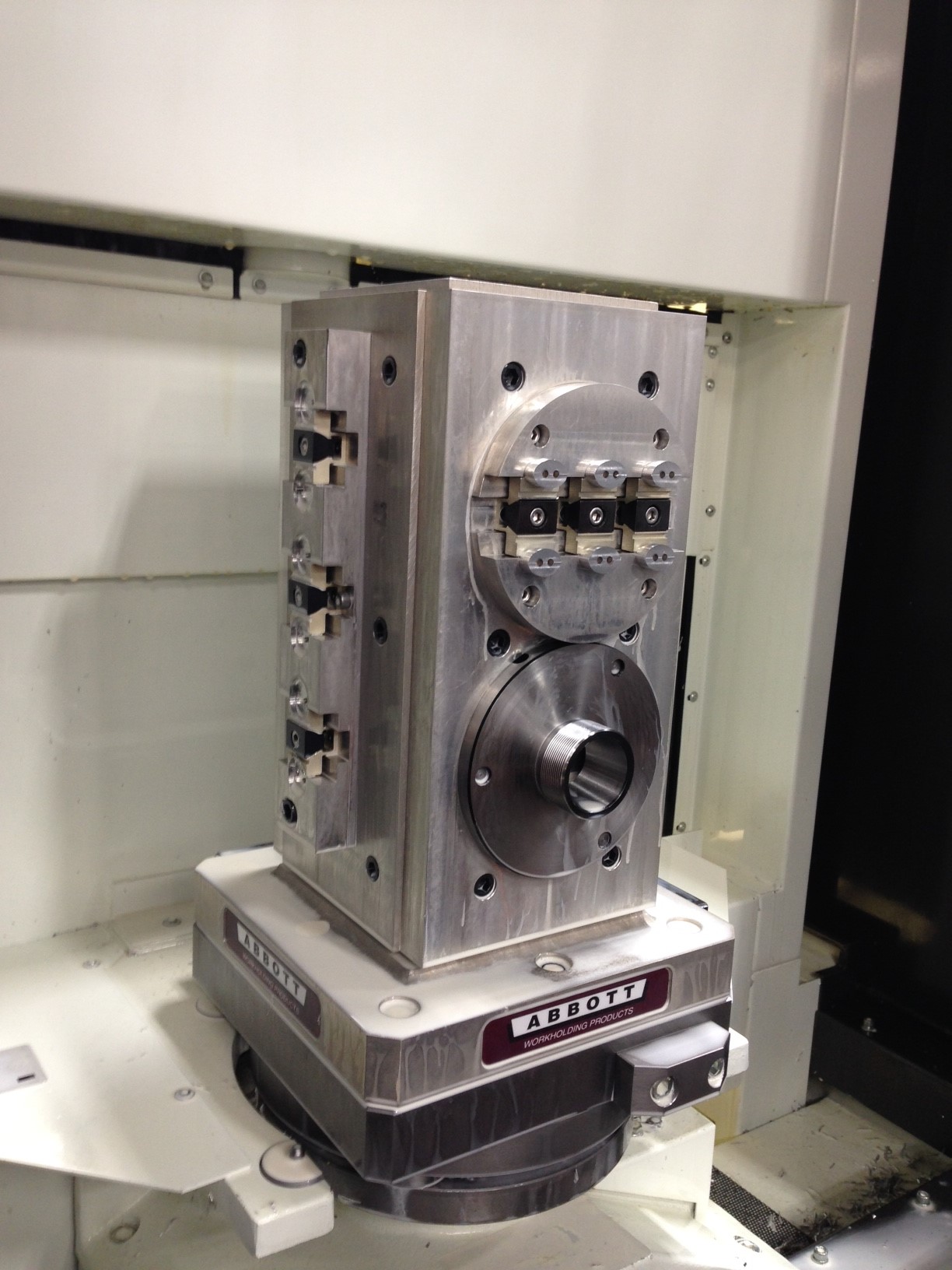

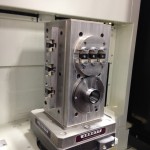

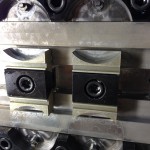

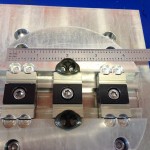

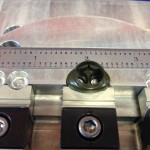

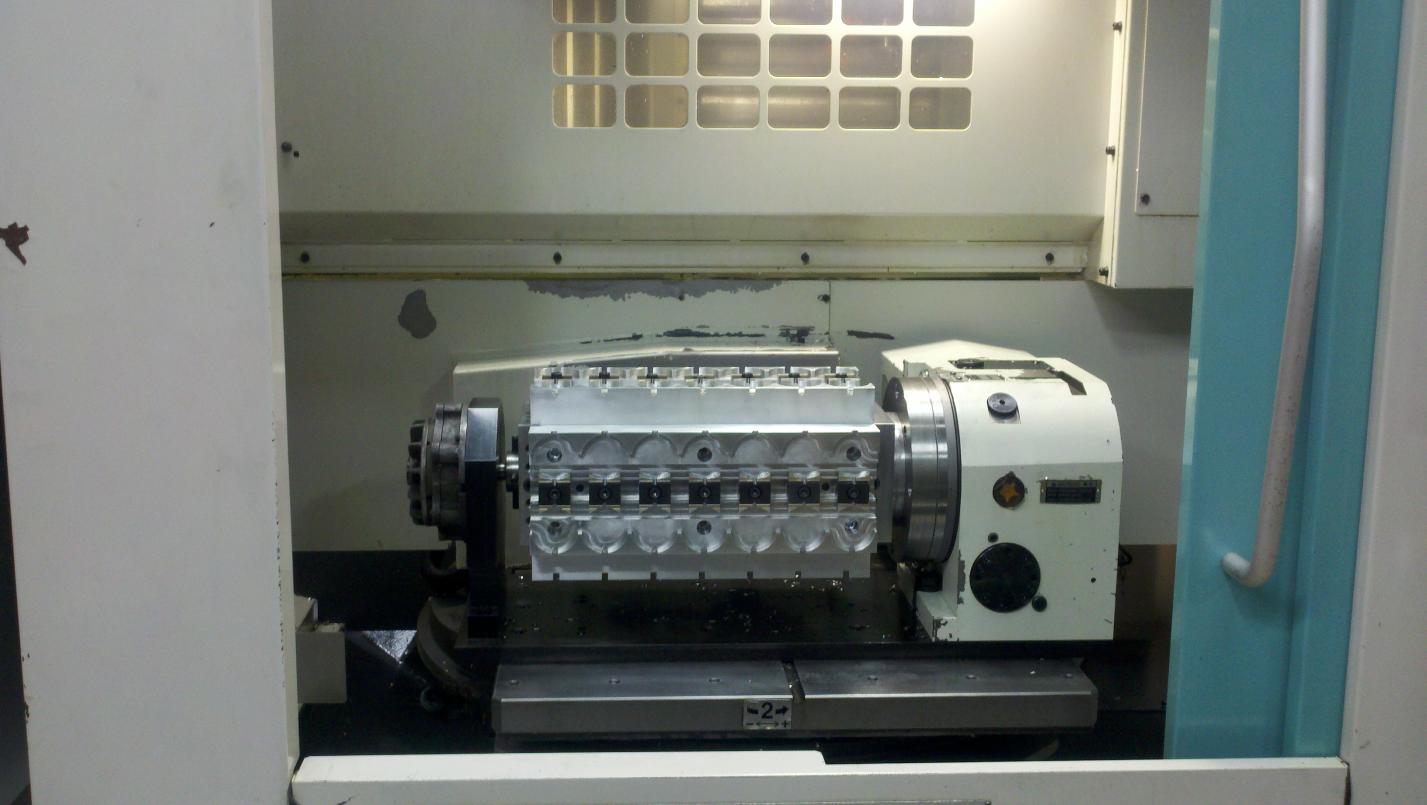

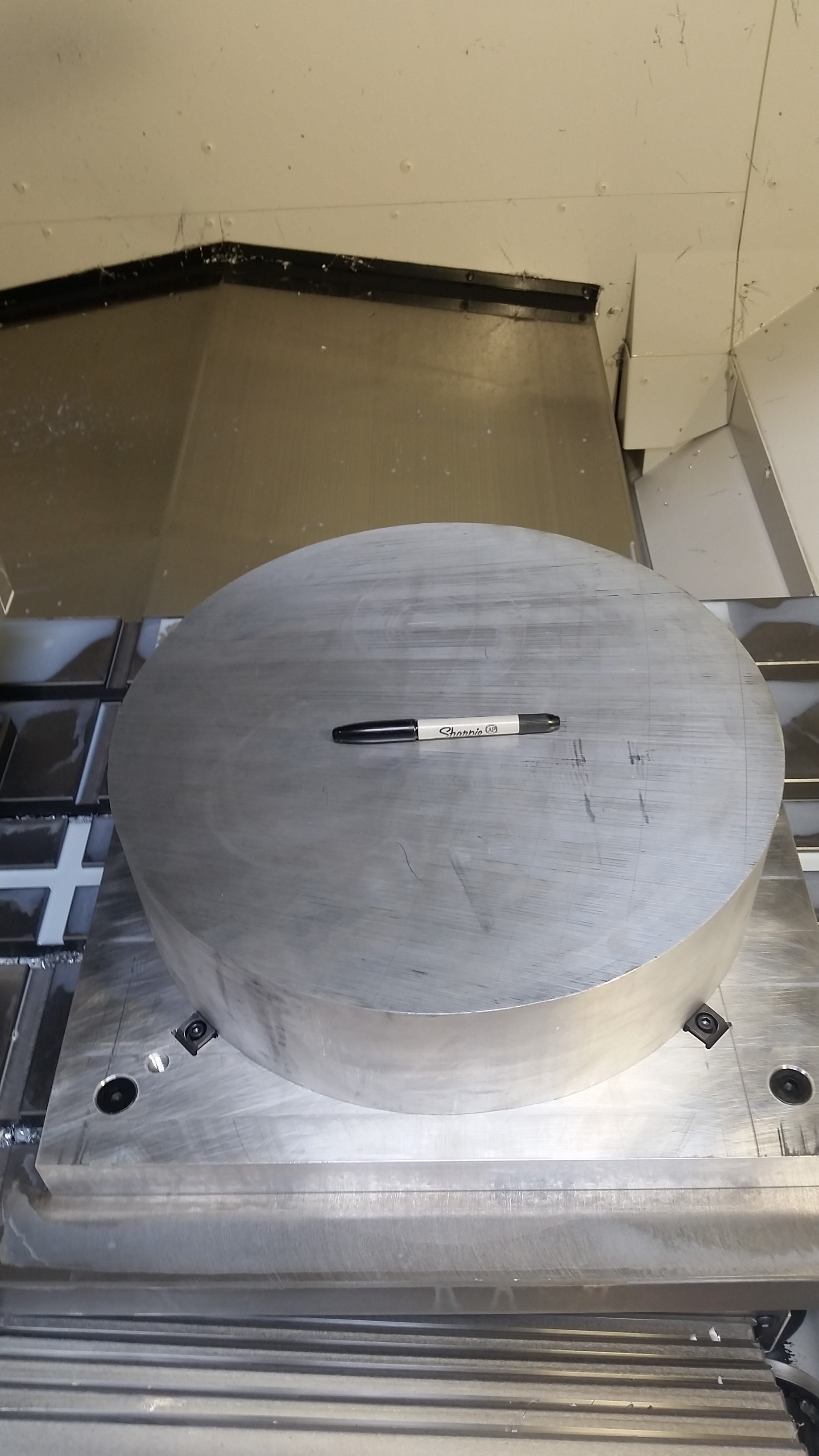

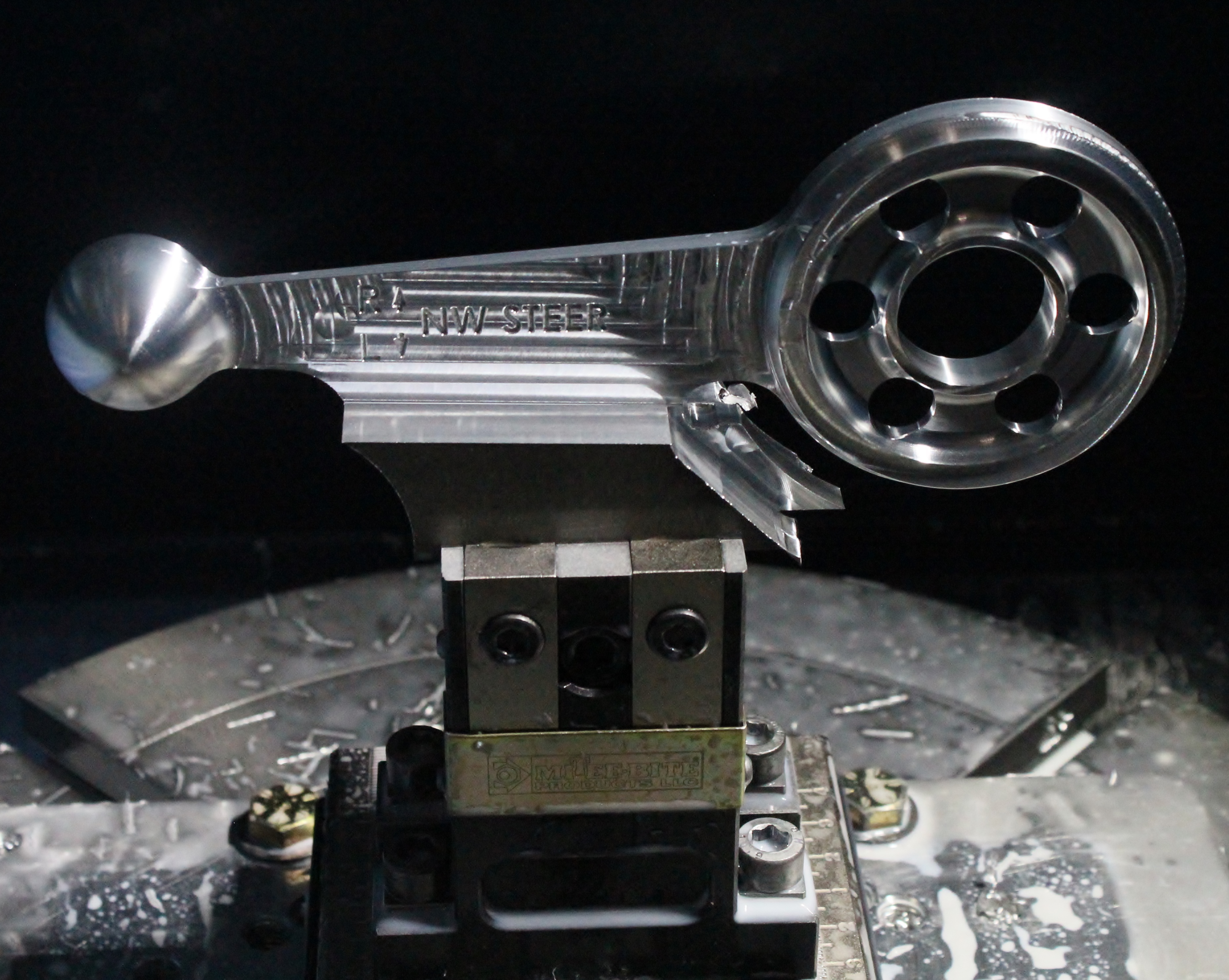

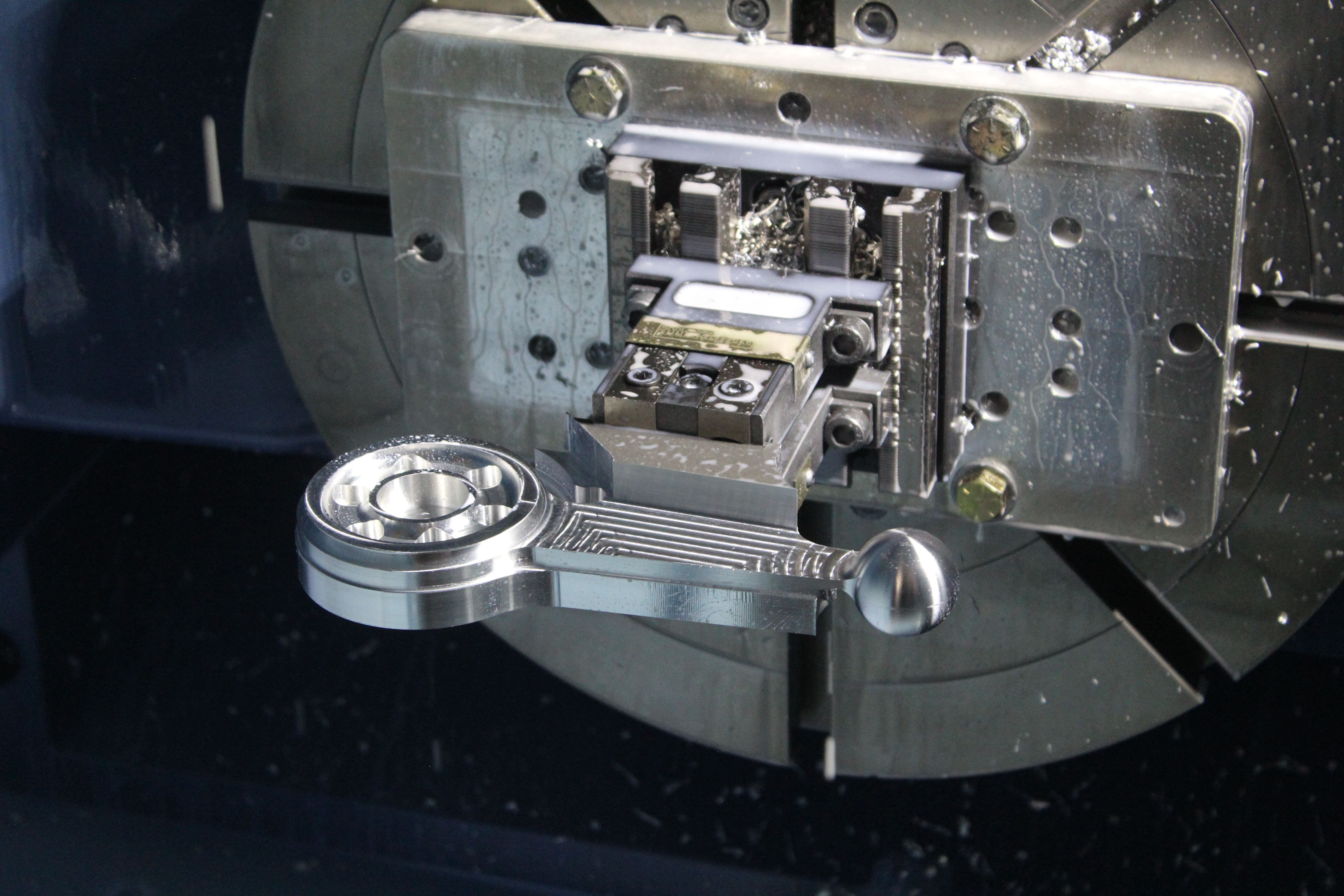

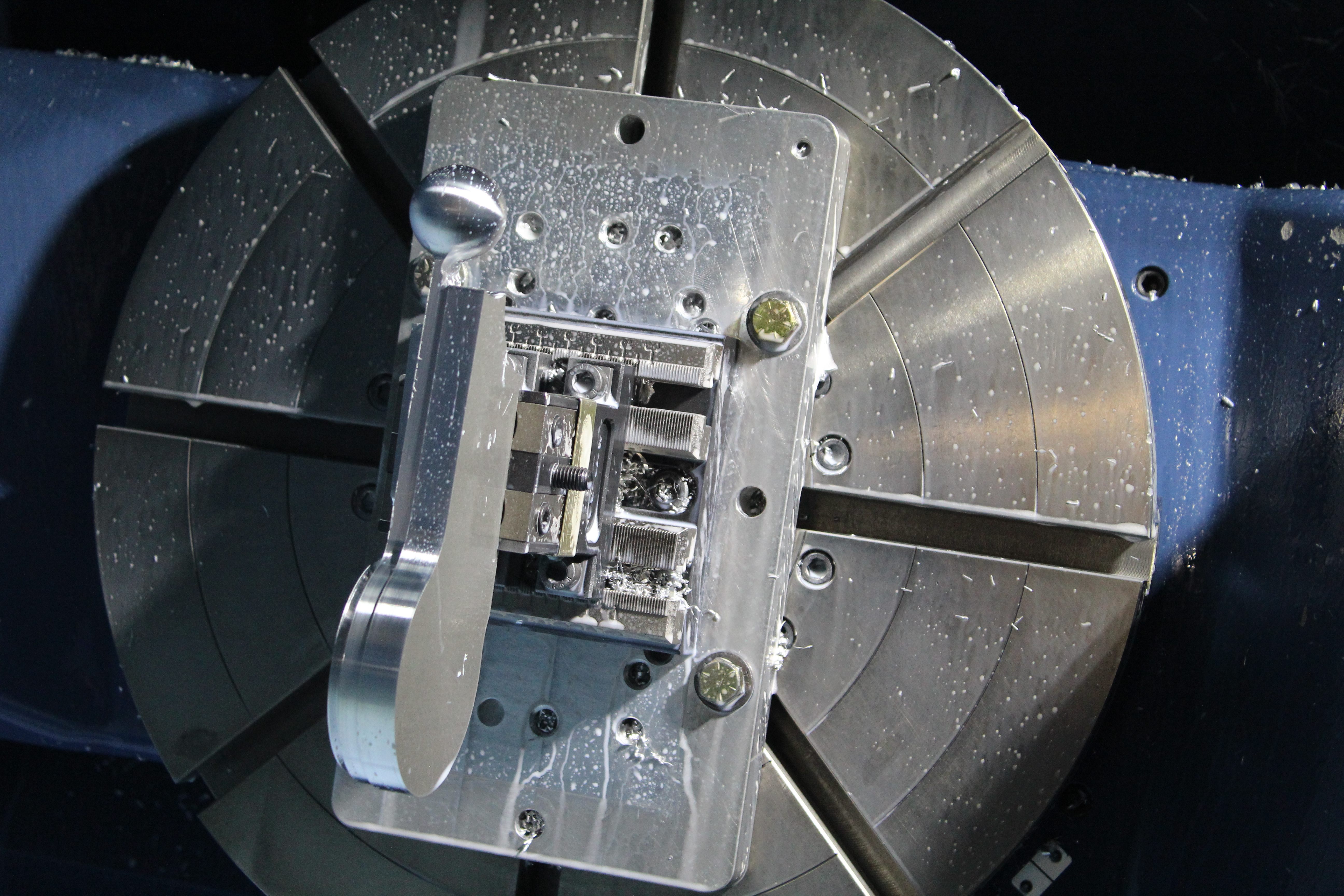

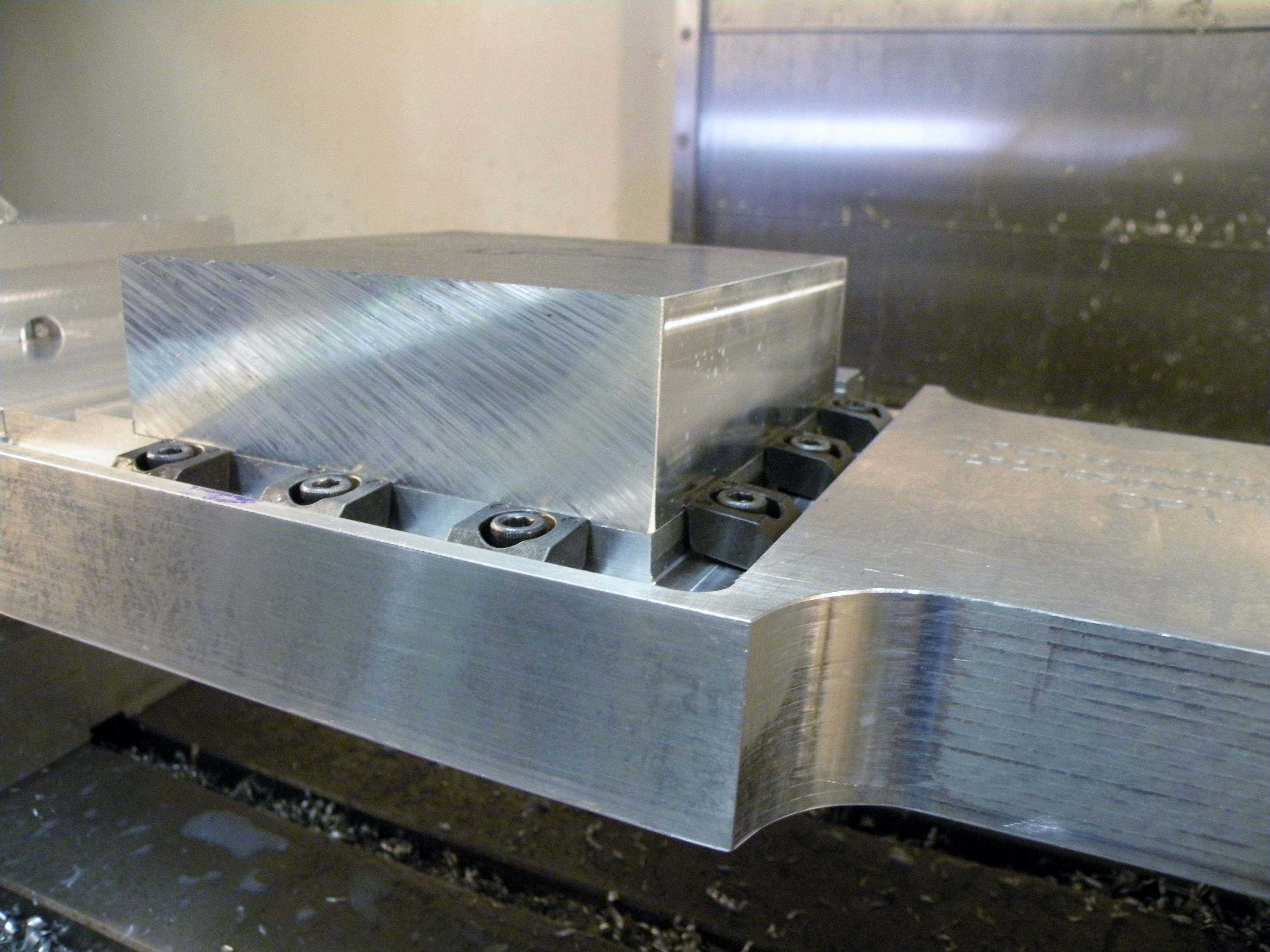

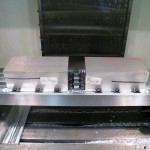

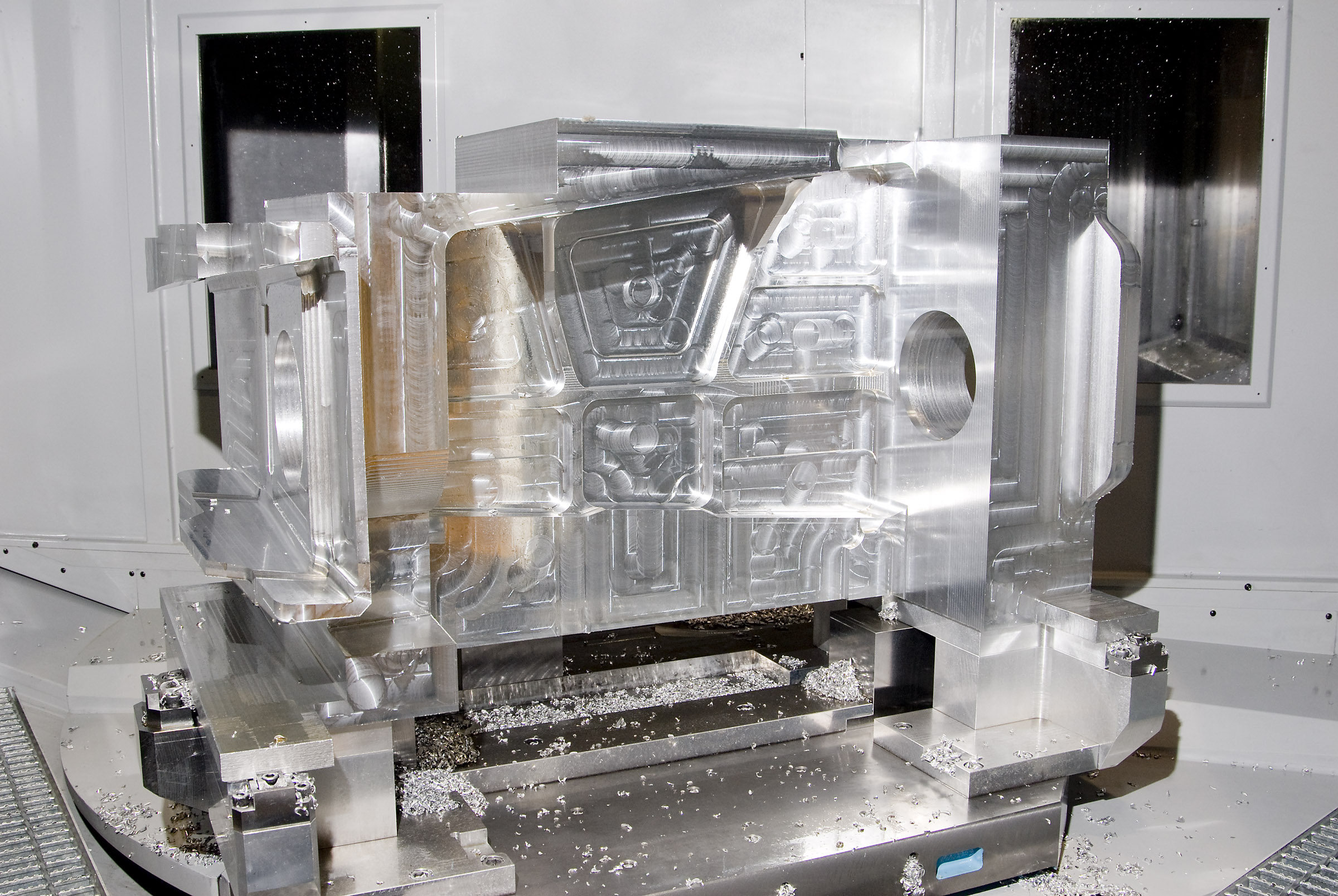

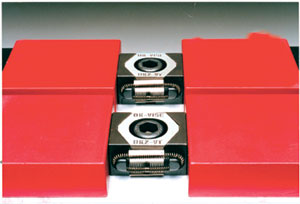

Smith & Wesson located in Springfield, MA is well known the world over, for it’s high quality gun manufacturing. It’s facility is over 500,000 square feet and they employee in excess of 600 people. Perhaps less known is the Specialty Services division of Smith & Wesson, which does various types of contract machining. Recently the Specialty Services Division was running jobs for Weatherby Rifle and had some applications of holding radius shaped parts on work cubes for several different work pieces. The difficulty of the set up was to clamp the pieces from the side, so the clamp would not be in the way and not take up too much valuable space. The engineer contacted their distributor, Kenneth Crosby Inc., who realized that because the parts were located in a rest block with a V, that the clamps would need to be wedge clamps with a fair amount of travel. This way the clamp could retract enough to exchange work pieces easily. OK-Vise® clamps by Mitee-Bite Products was chosen because of their compact size and strong holding force of over 6000 lbs. These clamps are self centering which was important to allow equal clamping force on each part. The hardened and ground clamps have a range of expansion of up to .280 which made part exchange easy. One of the jobs was clamping forgings before machining so the serrated edges provided extra grip for better rigidity.

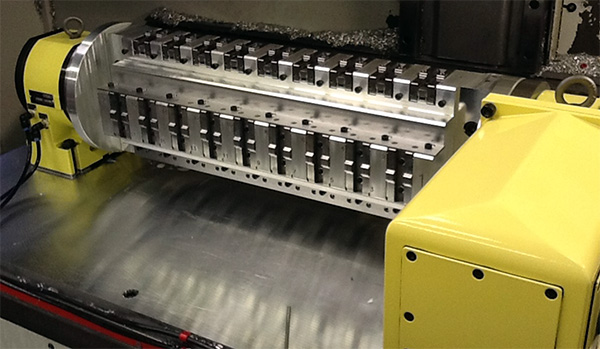

Recently the Specialty Services Division was running jobs for Weatherby Rifle and had some applications of holding radius shaped parts on work cubes for several different work pieces. The difficulty of the set up was to clamp the pieces from the side, so the clamp would not be in the way and not take up too much valuable space. The engineer contacted their distributor, Kenneth Crosby Inc., who realized that because the parts were located in a rest block with a V, that the clamps would need to be wedge clamps with a fair amount of travel. This way the clamp could retract enough to exchange work pieces easily. OK-Vise® clamps by Mitee-Bite Products was chosen because of their compact size and strong holding force of over 6000 lbs. These clamps are self centering which was important to allow equal clamping force on each part. The hardened and ground clamps have a range of expansion of up to .280 which made part exchange easy. One of the jobs was clamping forgings before machining so the serrated edges provided extra grip for better rigidity.

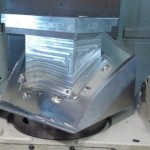

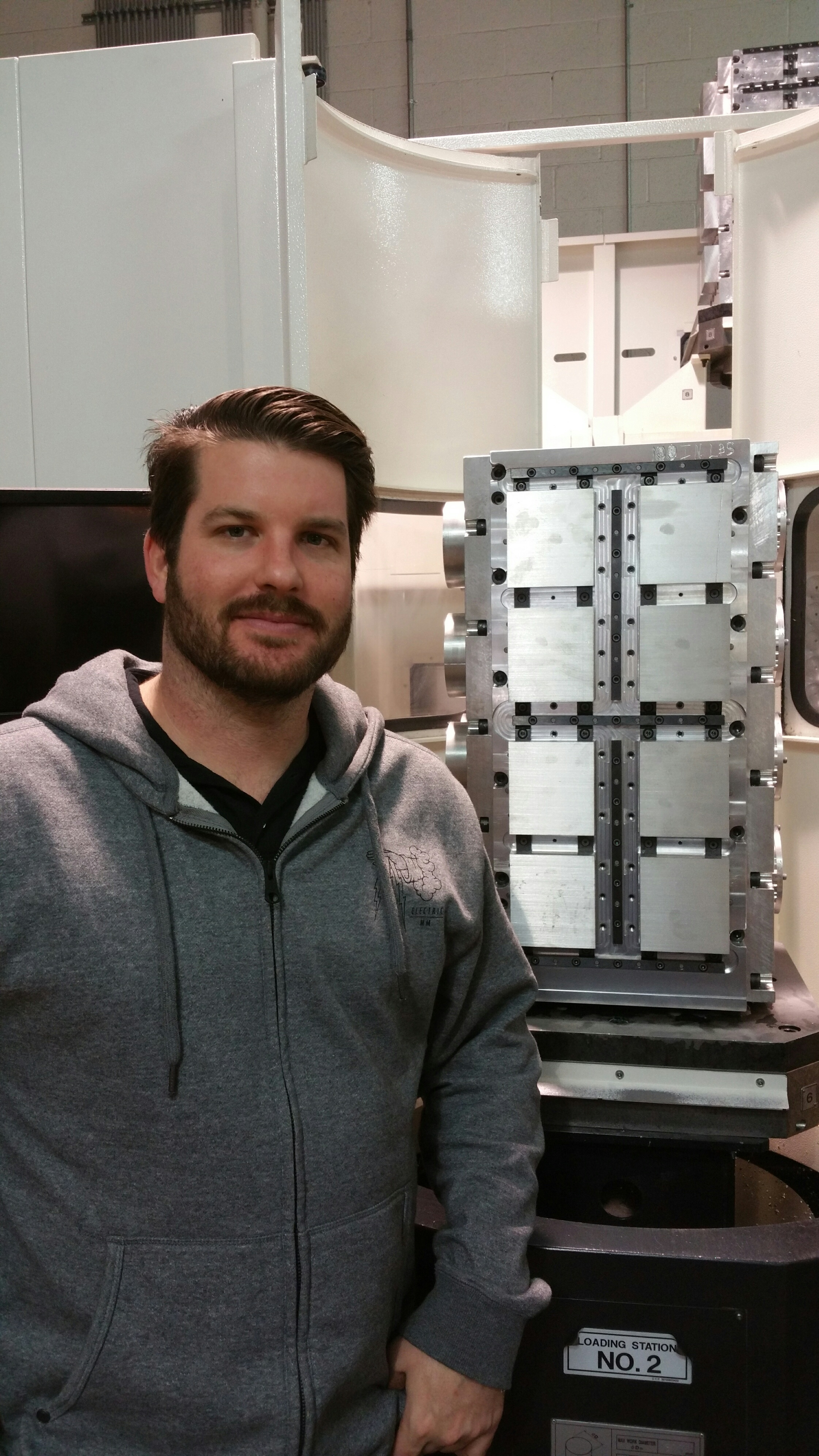

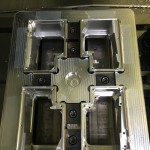

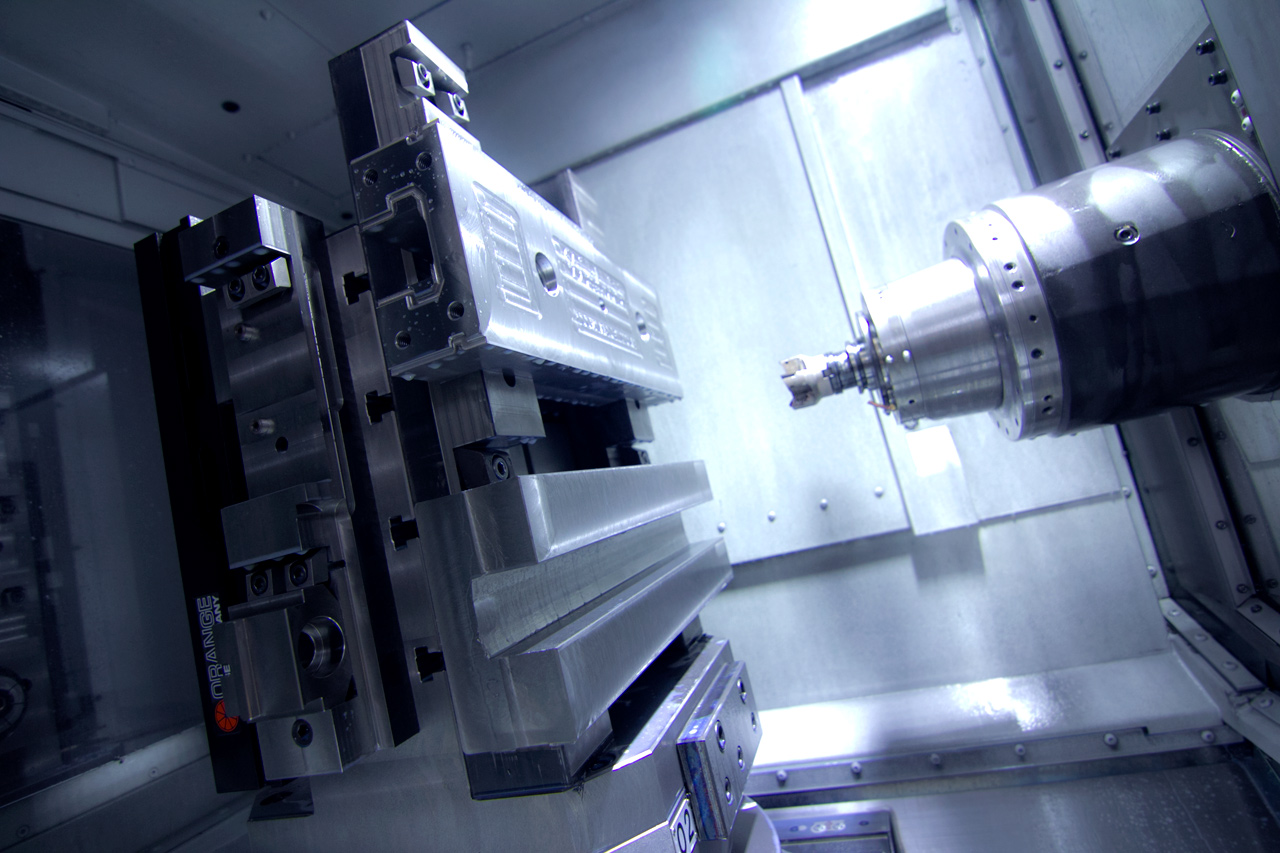

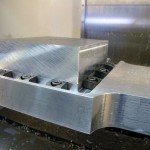

Quality Design & Mfg. of Oxford, CT has been in the machining business for over 20 years. The owners, Marty and Sue Martovich have recently developed a joint venture with Richard Grano. With the new management and change of direction, QDM moved to a larger more modern high tech facility to accommodate additional machinery acquired for larger production jobs.

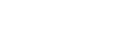

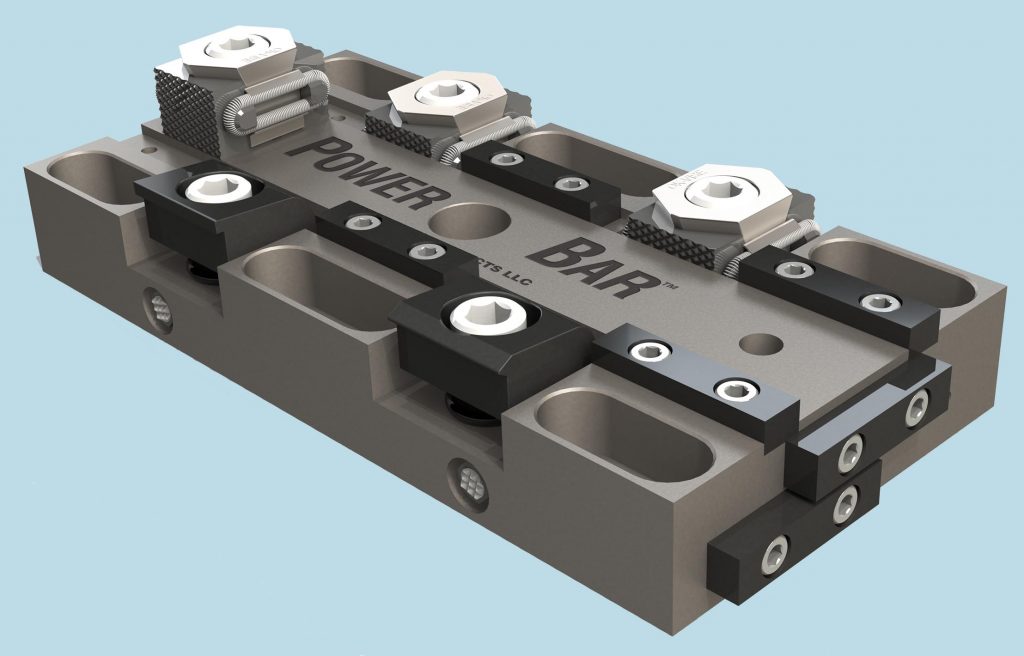

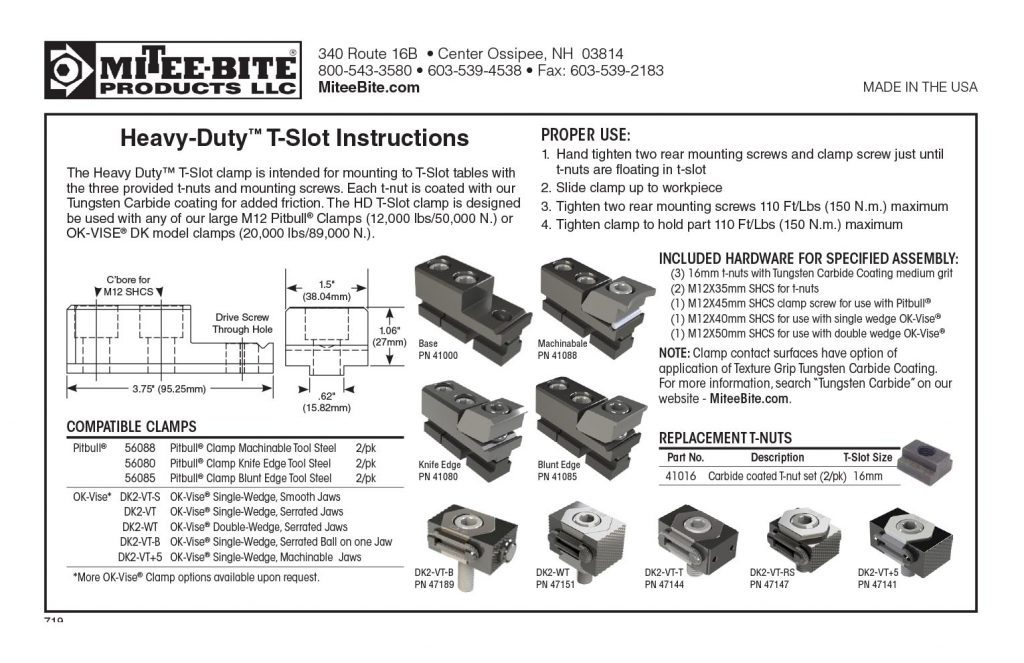

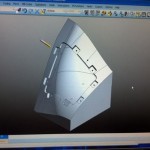

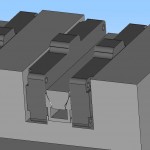

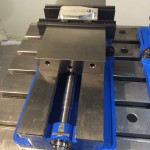

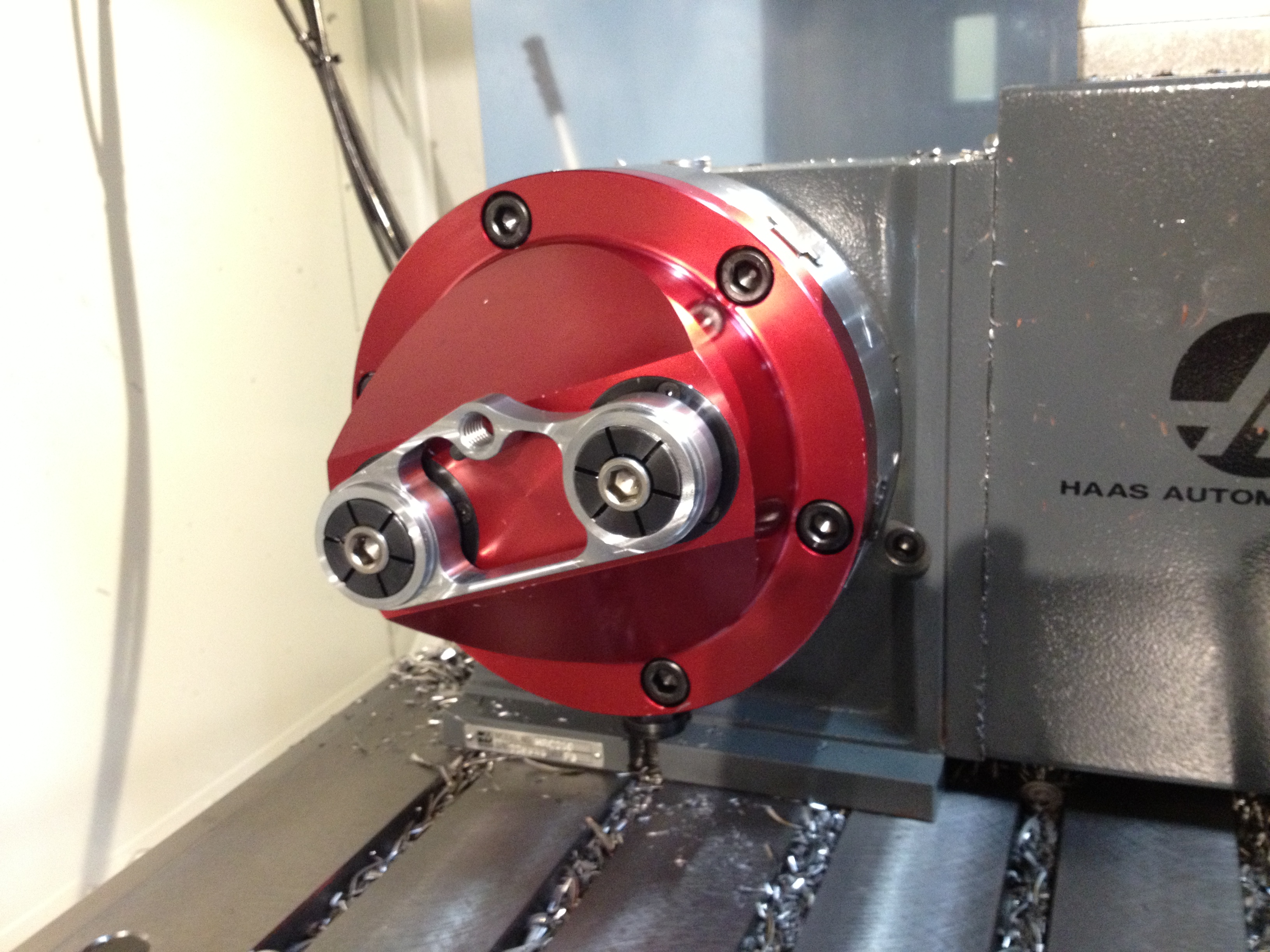

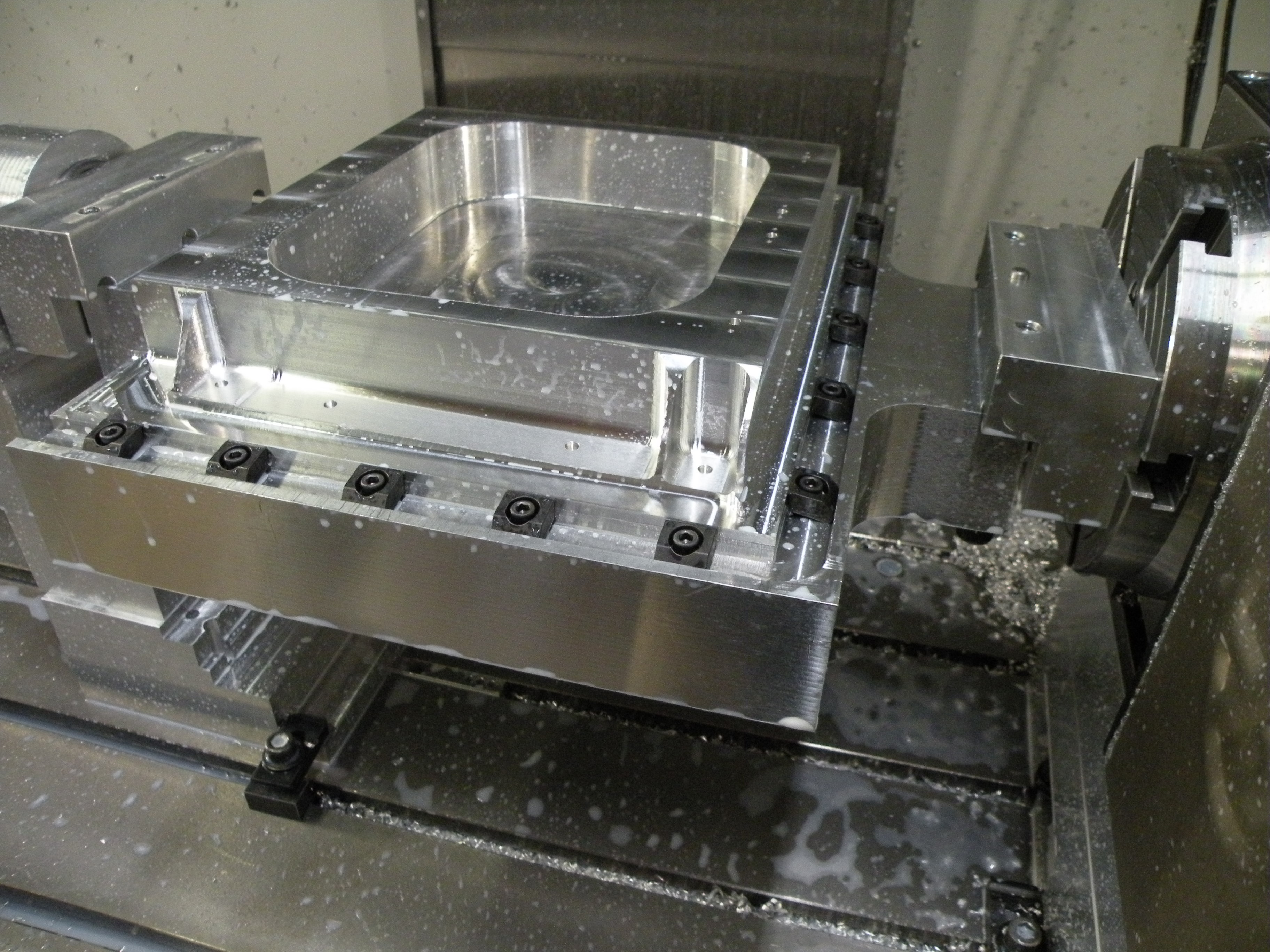

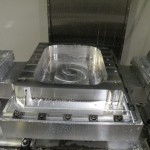

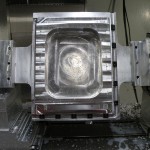

Quality Design & Mfg. of Oxford, CT has been in the machining business for over 20 years. The owners, Marty and Sue Martovich have recently developed a joint venture with Richard Grano. With the new management and change of direction, QDM moved to a larger more modern high tech facility to accommodate additional machinery acquired for larger production jobs. The OK-VISE® clamp is a wedge activated clamp. As the screw is tightened, the clamp expands and pulls the workpiece down at the same time. Small in size and high in clamping force, this low profile clamp is available in many different sizes.

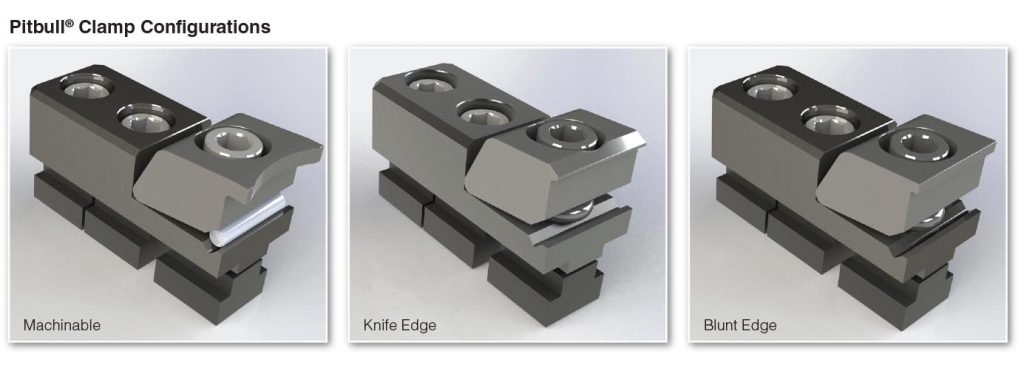

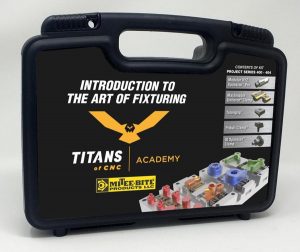

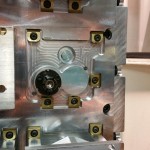

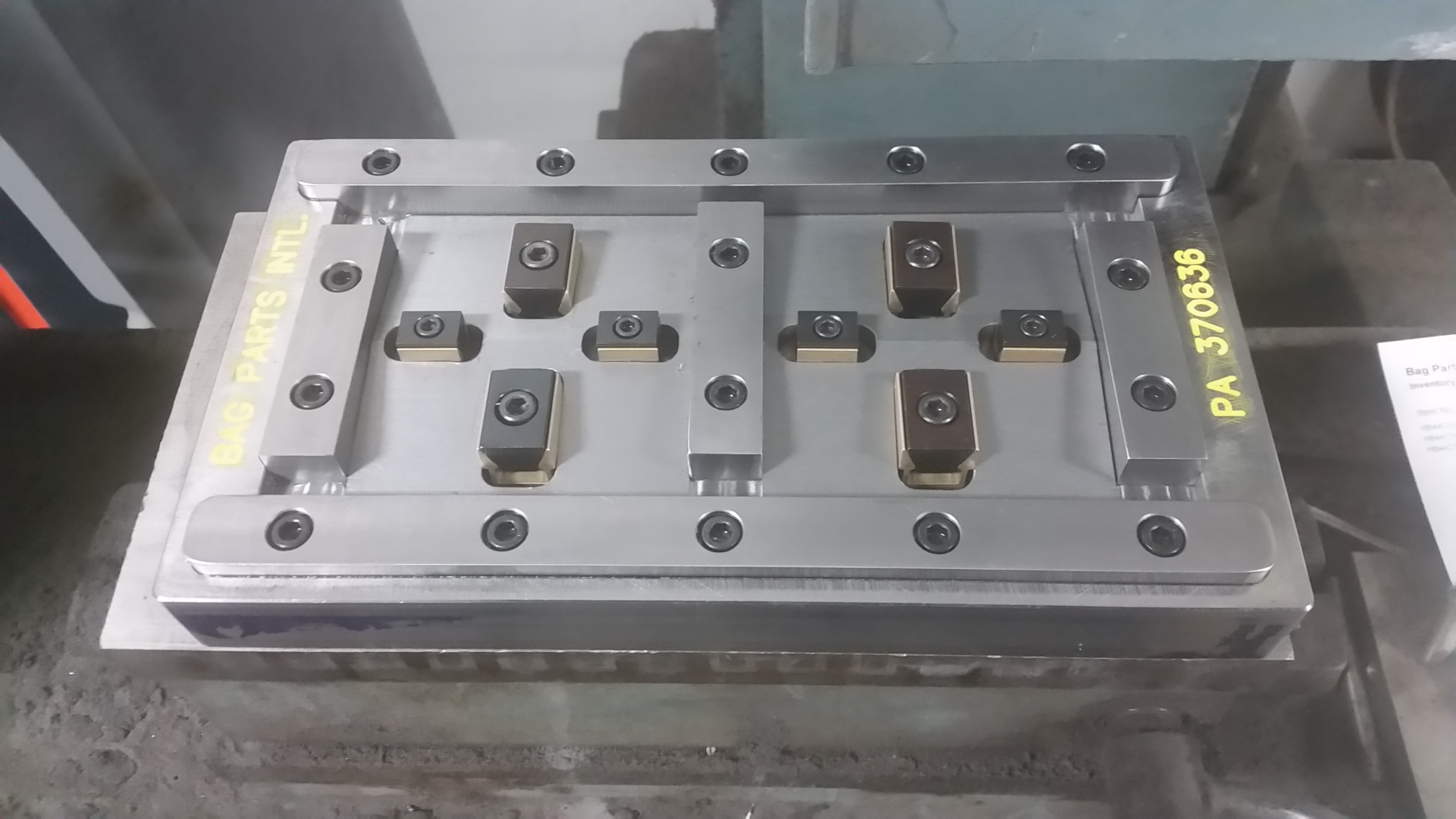

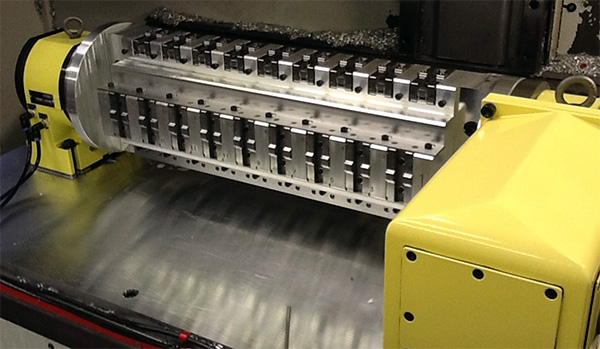

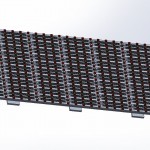

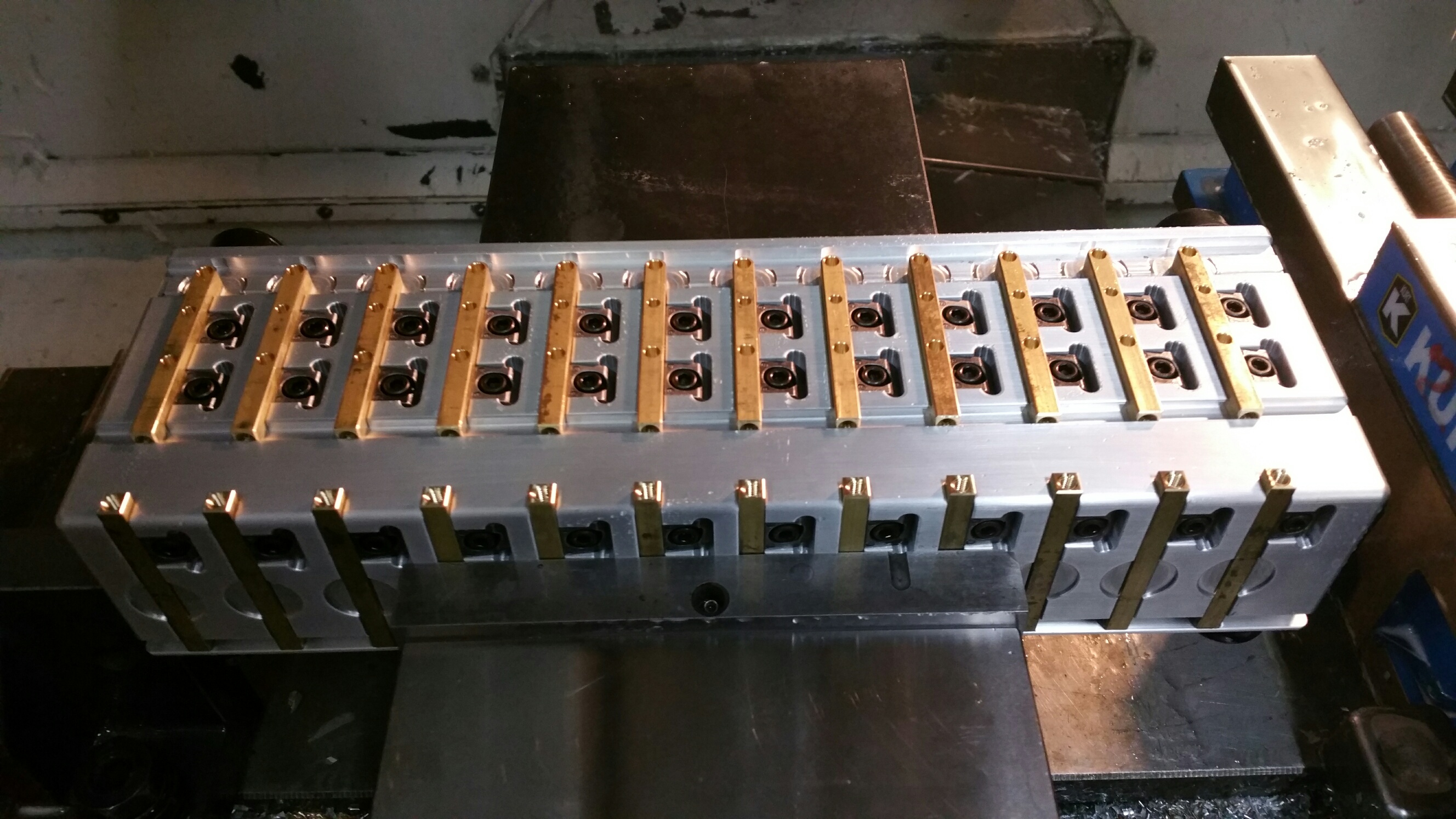

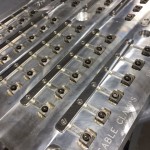

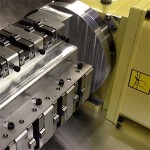

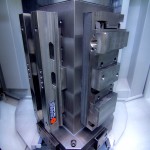

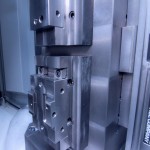

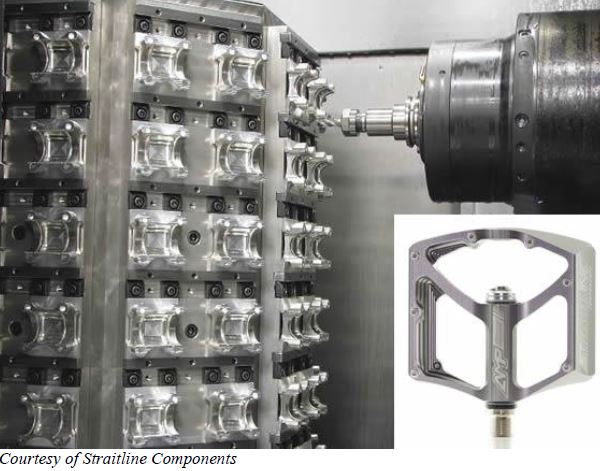

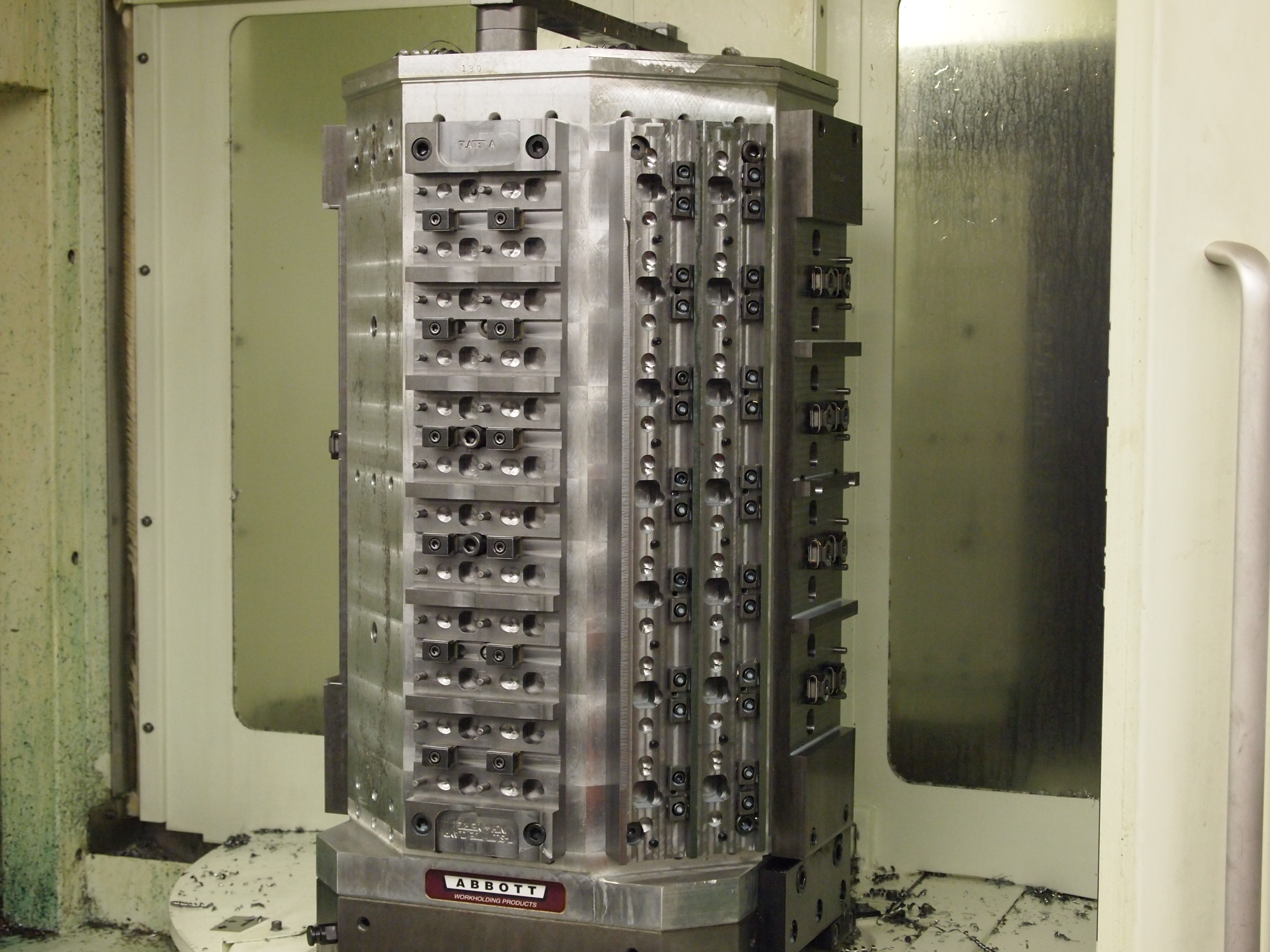

The OK-VISE® clamp is a wedge activated clamp. As the screw is tightened, the clamp expands and pulls the workpiece down at the same time. Small in size and high in clamping force, this low profile clamp is available in many different sizes. Mitee-Bite Products specializes in low profile edge clamps in several different styles and sizes for jigs and fixtures, including a range for micro machining. The miniature clamps are available in cam action design, wedge design and Pitbull® design which bites in and pulls down. Some of these clamps are less than 1/8 inch high and 3/8 square allowing for dense fixture loading of miniature work pieces. Mitee-Bite’s clamps can be operated manually and the wedge and Pitbull® clamps can be activated using a hex type torque driver for quicker loading and unloading. The photos show density loading and the different type of clamps.

Mitee-Bite Products specializes in low profile edge clamps in several different styles and sizes for jigs and fixtures, including a range for micro machining. The miniature clamps are available in cam action design, wedge design and Pitbull® design which bites in and pulls down. Some of these clamps are less than 1/8 inch high and 3/8 square allowing for dense fixture loading of miniature work pieces. Mitee-Bite’s clamps can be operated manually and the wedge and Pitbull® clamps can be activated using a hex type torque driver for quicker loading and unloading. The photos show density loading and the different type of clamps.